- validation of the GAMP5 computer system,

- FDA 21CFR11 requirements for e-signatures and e-records,

- process modelling based on ISA S88.01.

Pharma

Automation system

Tools

We use established universal tools:

- PLC level: Siemens, others upon request,

- SCADA: GE iFix, Siemens WinCC, others upon request,

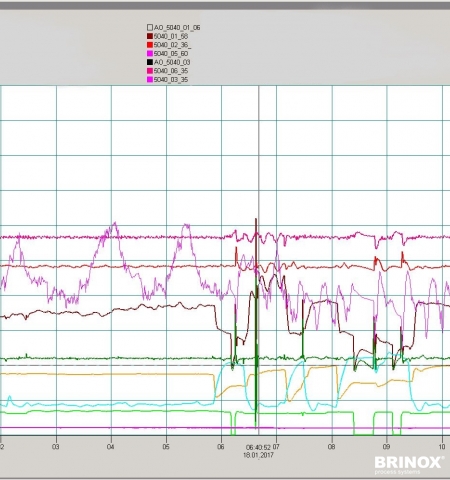

- production informatics level: MS SQL and Reporting server, MS .NET, GE Historian,

- with the open concept we are able to integrate the solution into the customer’s environment.

The automation system ensures

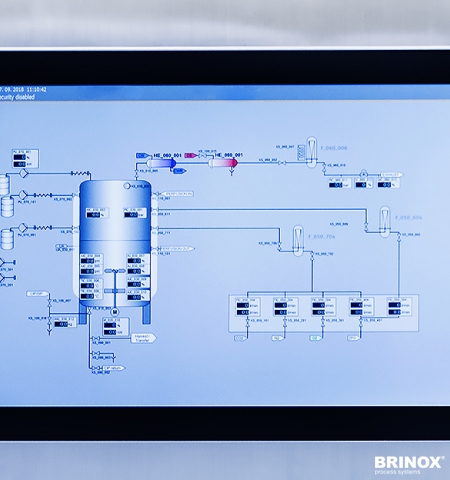

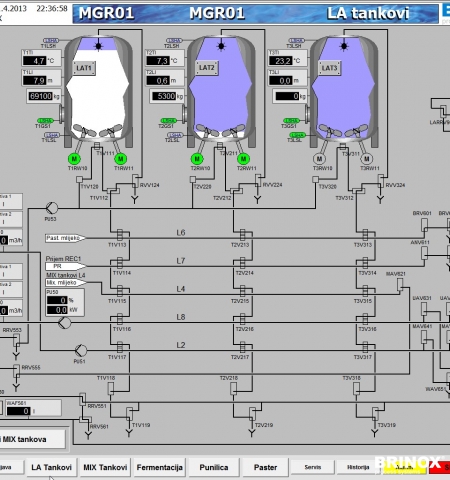

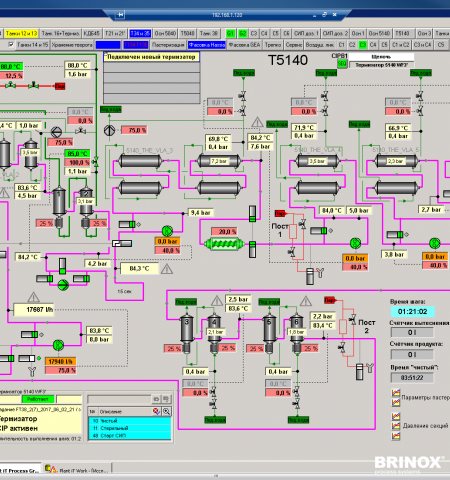

- The advanced SCADA visualisation allows to control all elements of a process (valves/motors, sensors).

- The use of the ISA S88.01 recipe system ensures a high level of automation and at the same time makes the process highly adaptable and allows good use of the process equipment.

- The modular hierarchic control system concept ensures the execution of the process in various procedure levels (stages, operations, unit procedures, procedures) and consequently the process optimisation and a faster introduction of new products.

- The user independently creates recipes based on the provided templates which protects their know-how and product.

- The recipe approval work process is based on e-signatures.

- The unit procedures run entirely on the PLC-level which ensures reliable operation and fast changeovers between individual steps.

- The recipe and process execution data, historic data and the Audit Trail provide an extensive database for electronic reporting.

- The FDA 21CFR11 support is based on Windows protection.

- The implementation of interfaces to other systems at the PLC level (supply of clean media, safety systems, etc.) and at the information level (MES, KPI).